Sublimation printing: Brilliant large-format printing as a real eye-catcher

Sublimation printing is one of the most popular printing processes when it comes to producing large-format textile advertising spaces. Read here how the printing process works, which advantages it offers and in which areas it can be optimally used!

What is sublimation printing?

The special feature of this process is that the ink is vaporized, i.e. sublimated, into the material to be printed. For this reason, this printing method is called sublimation. TREVISION can use this printing method on textiles made of polyester (at least 60-70%).

In principle, it is also possible to print on other materials such as cotton. However, this requires other inks and machines.

What materials are used in large format textile printing?

Sublimation printing uses special water-based inks that immediately change to a gaseous state under high pressure and heat. The decorative fabric must contain at least 60 to 70 percent polyester so that the ink can react with the base material.

TREVISION produces large format image products by direct printing on a polyester mesh with approx. 200g/m². The polyester materials are available in a wide variety of haptic finishes, including structures very similar to PVC mesh. Already more than half of our decorative fabrics are also made of recycled polyester.

The printing materials for sublimation printing are up to 3.2 meters wide and versatile with individual textile frame systems. If larger formats are required, they are sewn together from several images.

How does sublimation large format printing work?

The printing process takes place in two steps, as the color quality directly after printing does not yet have the desired color saturation and color depth. Only after fixing the color pigments do you get the final color result in high quality.

1. Design printing

In the first step, the design is printed onto the polyester textile using sublimation inks. The decorative fabric then runs through a dryer to draw the water out of the fabric by evaporation. The dye of the ink remains in solid form in the textile.

2. Fixation

This is where sublimation comes into play. Under high pressure and at a temperature of around 190°C, the solid dye transforms into a gas. At the same time, the pores of the polymer open up. The dye can now penetrate the fibers of the fabric as a gas and combine with them.

When the temperature drops, the pores close, the gas returns to the solid state and is now part of the polymer. This is also the reason why sublimation cannot be done on natural materials like 100% cotton. Natural fibers do not have pores that open.

What are the advantages of sublimation printing?

With sublimation, decorative fabrics can be printed in very high quality. Since it is a digital printing process, all imaginable colors are possible. The result is a color-brilliant print that is versatile. The greatest advantages lie in the following properties:

- Odorless: Sublimation prints are odorless and solvent-free – a big advantage indoors!

- High durability: Since the inks are anchored in the textile fibers, the ink application itself cannot be rubbed off. Unlike other printing processes, the textile and thus the print remain durable for a longer period of time (wash resistance).

- Handling: Sublimation prints are easy to fold up because there is no ink adhering to the surface that could break or be rubbed off. This results in very small transport dimensions.

- Covering large areas: Decorative fabrics can be used to cover large areas. Individually designable profile systems with textile coverings make it possible.

- Easy mounting: The frame systems, with and without LED backlights, can be mounted without tools and in an uncomplicated way.

For which applications is large-format textile printing suitable?

Sublimation printing is mainly used indoors. High color brilliance and odor neutrality make the fabric prints attractive as decoration, background and room divider for use in store design and event areas (e.g. retail, trade fairs, congresses, exhibitions, stage design). For outdoor use, sublimation printing is only suitable to a limited extent. The material itself is very robust, but as with all fabrics, the decorative fabric quickly absorbs dirt and can thus impair the appearance.

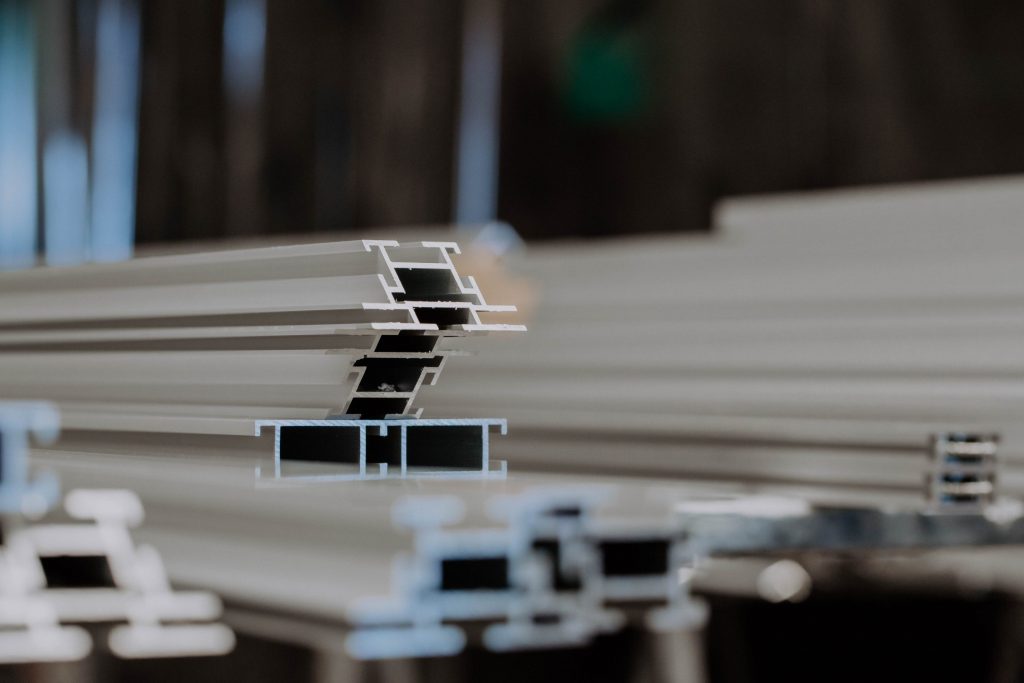

How does the profile system for large-format textile printing work?

A silicone welt is sewn all around the individual fabric prints. This allows the prints to be simply pressed into the profile and can thus be changed quickly and easily. The frameless look of the TREVISION systems puts the motif in the center of attention – without any annoying mounting techniques! For large formats, the profiles have an inwardly inclined keder mount. This strengthens the fixation of the textile print in the frame.

Conclusion: sublimation printing for interior design

Sublimation produces the most durable and brilliantly colored print. Especially due to its odorless property, sublimation printing is perfect for large-format image design of indoor sales and presentation areas. A dedicated Trevision Smart Store concept team develops large-format complete solutions for this area of application – from planning to implementation and installation of the lighting and framing solutions. For more information and specific questions about sublimation printing, please contact us!